From 100% green electricity:

Sustainably produced perlite

Manufacturers of insulation materials, construction chemicals and polymers listen up!

Those who know perlite think first and foremost of volcanic rock, which has been expanded with the help of high temperatures based on gas. Up until now, this product group has always been available on the market reliably and at low prices. As a result of the current geopolitical tensions, however, this has unfortunately changed in recent months.

With our MagSpheres® P‑series we offer you perlite that is permanently available, attractively priced, and very sustainable.

Perlite is based on volcanic rock. By heating the rock to over 1,000 °C, it expands and increases its surface, thus acquiring properties that are of interest to a wide variety of industries. For example, perlite is an ideal insulating material or is suitable for reducing the density of materials while maintaining the same volume.

To generate such high temperatures in the treatment process, gas is traditionally used in industry. However, its use has recently come under criticism and has become increasingly uneconomical. As a result, perlite are no longer available on the market as usual or have become very expensive.

MagSpheres® P‑series perlite has the advantage of being expanded in furnaces that are electrically powered by 100% green electricity in Europe. In addition to the inefficiency of gas, innovations in electric furnaces also contribute to the fact that electrically expanded perlites have now become competitive in price. Another effect is that this type of perlite is permanently available on the market due to its independence from gas.

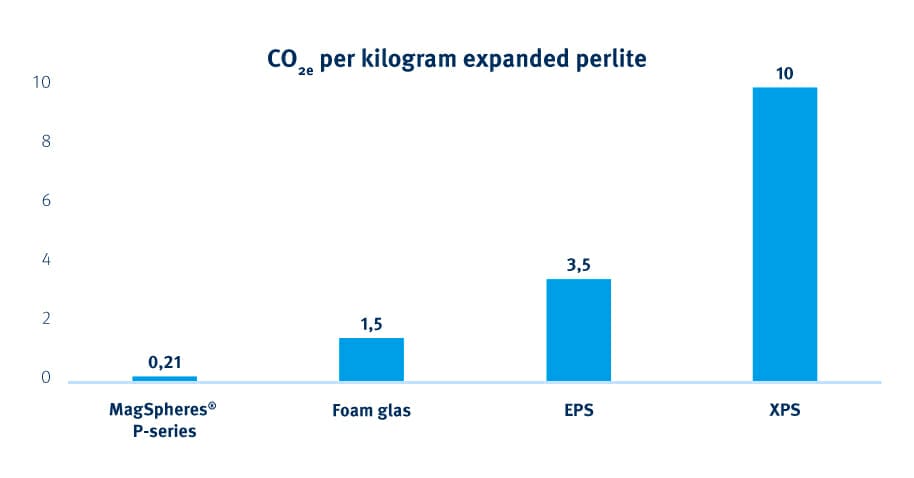

The biggest advantage of our electrically expanded MagSpheres® perlite series is that they have a very low carbon footprint due to the use of green electricity. Depending on the origin of the raw material used, the CO2 footprint is 180 — 210 grams of CO2 equivalent (CO2e) per kilogram. They are superior to other, functionally similar materials. Foam glass, for example, has a CO2e value of 1,000 – 1,500 grams, EPS a value of 3.5 kg and XPS a value of around 10 kg. The use of the MagSpheres® P‑series instead of other materials can thus significantly improve the carbon footprint of entire construction projects.

In addition, the use of our MagSpheres® also has an impact on other relevant areas compared with the use of alternative materials and results, among other things, in a reduction in photochemical ozone formation, acidification, particulate matter, and carcinogenic and non-carcinogenic effects. Especially in comparison to biogenic materials, our product scores with a very low land consumption.

Source: Footprint Consult e.U. (2019) – Umweltbeurteilung von Blähperlit

Contact us now

Talk to us and let us advise you personally. For this purpose, we are also happy to provide you with a sample case for a joint virtual workshop without obligation and free of charge.